TL;DR

Our two most popular steel backups survived inside a ceramic furnace that was on for 12 hours, reaching a peak temperature of 1150 °C (2102 °F). Additionally, both backups were fully recovered and no data was lost.

Introduction

We are really excited to announce that both of our stainless steel backup survived a live ceramic furnace for 12 hours straight (+ another 14 hours to cool), with a peak temperature of 1150 °C (2102 °F). And not only they survived, they are completely legible and no data loss occurred, both backups were fully recovered.

We confidently believe that this stress test simulated an extremely severe house fire on both steel plates.

This test was made possible thanks to Juan de Dios Sanchez, who specializes in large-scale Raku ceramics, an ancient and very fine Japanese technique which only a few people in the world still practice. His factory is located in Morelos, Mexico and it's called Arte Kuan. He let me place the steel plates inside the furnace which he obviously used for other ceramic sculptures.

Facts about the plates:

- Both plates are AISI 304 Stainless Steel.

- Both plates have a melting point of 1450 °C.

- Both plates are Gauge 14 (~2mm thick).

- Both plates have fiber laser etched guides.

Facts about this stress test:

- The temperature inside the furnace was incremental.

- One plate was positioned flat and the other one reclined on a brick.

- The peak temperature was 1150 °C (2102 °F) and was maintained for 1 hour.

- The furnace was on for 12 hours, but remained closed for another 15 hours after turning it off (27 hours total).

Purpose of this stress test:

- Show the endurance of this steel against extreme heat.

- Simulate an extreme house fire on the backups.

- See if all data of the backup is recovered.

Temperature graph

One of Juan's workers was kind enough to show me their record of the furnace's temperature, they did a reading of the thermostat every 15 minutes from 6:30 am to 6:00 pm.

Please note that the furnace was turned off at 6:00 pm but remained closed until the next morning at 9:00 am, an extra 15 hours which I do not have the graph for, but it's safe to say it remained very hot inside the furnace for a good few hours after it was turned off.

Samples (before the test)

First I'll showcase both fully stamped steel backups before the test with high detail to perfectly illustrate how deep the marks made by the stamps and center punch really are. I purposely chose the most scratched plates to avoid wasting a perfectly shiny one.

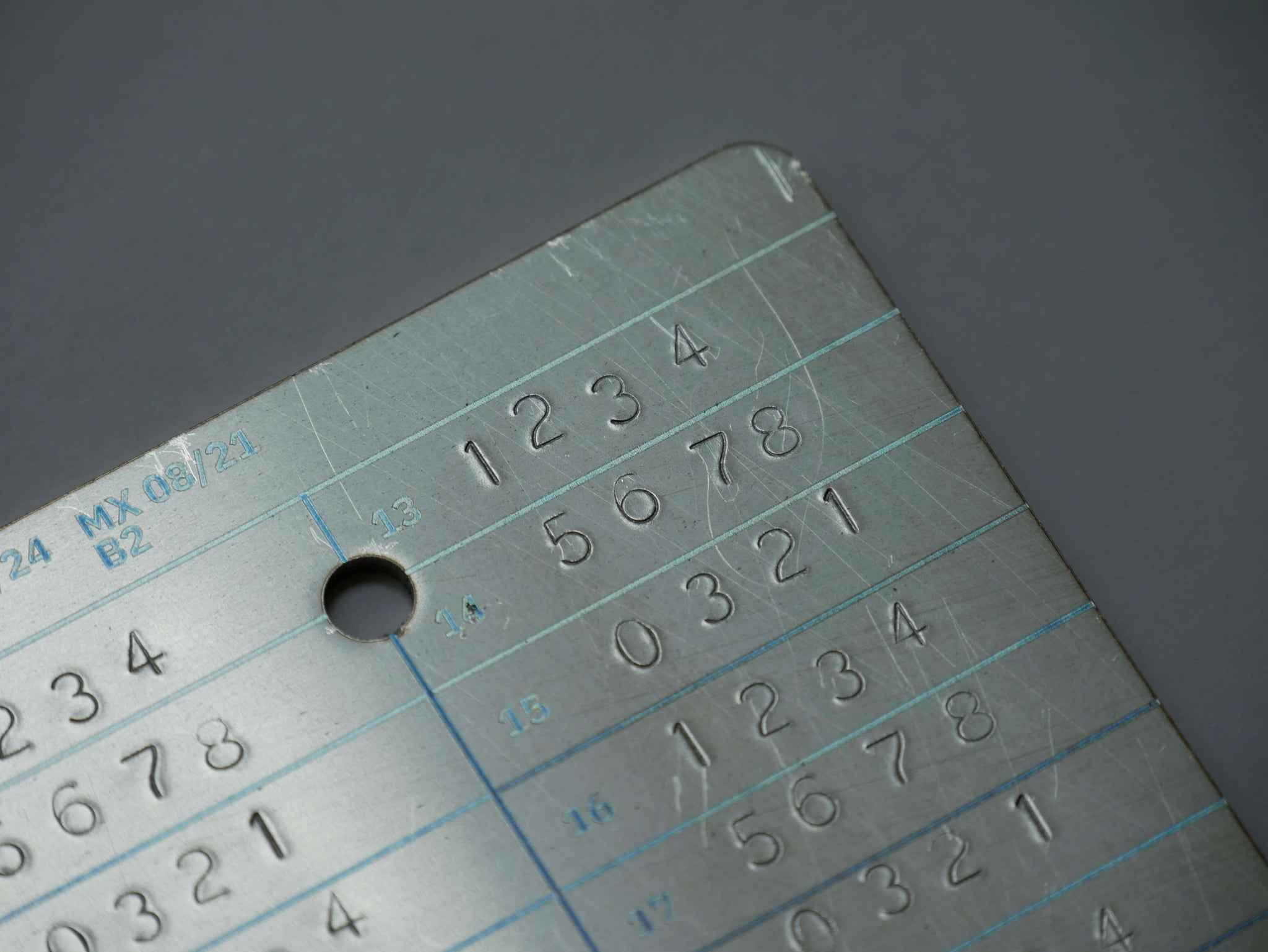

Steel backup 1 (Plate S): Marks made with numerical stamps, which leave a direct stamp of the number in the steel.

Fig. 1: Fully stamped Plate S, front and back.

Fig. 1: Fully stamped Plate S, front and back.

Fig. 2: Fully stamped Plate S, angle view.

Fig. 2: Fully stamped Plate S, angle view.

Fig. 3: Fully stamped Plate S, close up.

Fig. 3: Fully stamped Plate S, close up.

Fig. 4: Fully stamped Plate S, macro zoom.

Fig. 4: Fully stamped Plate S, macro zoom.

Steel backup 2 (Board S): Marks made with a center punch tool, which leaves a small hole in the steel.

Fig. 5: Fully stamped Board S, front and back.

Fig. 5: Fully stamped Board S, front and back.

Fig. 6: Fully stamped Board S, angle view.

Fig. 6: Fully stamped Board S, angle view.

Fig. 7: Fully stamped Board S, close up.

Fig. 7: Fully stamped Board S, close up.

Fig. 8: Fully stamped Board S, macro shot.

Fig. 8: Fully stamped Board S, macro shot.

The setup

Pictures one day before the test, this is how I setup both plates.

Fig. 9: The ceramic furnace one day before the test.

Fig. 9: The ceramic furnace one day before the test.

Fig. 10: The positioning of both plates, I decided to put one flat and the other one reclined in the brick.

Fig. 10: The positioning of both plates, I decided to put one flat and the other one reclined in the brick.

The test

On April 12 at 6:30 am the test had begun, the furnace was on. Juan told me the peak temperature was gonna be reached at around 4:30 pm so I went to the factory at that time to photograph the live furnace and the thermostat.

Fig. 11: Outside view of the live furnace.

Fig. 11: Outside view of the live furnace.

Fig. 12: Juan let me peek inside the furnace via a small hole that he uncovered on one of the sides.

Fig. 12: Juan let me peek inside the furnace via a small hole that he uncovered on one of the sides.

Fig. 13: Picture of the thermostat at peak temperature, they maintained the furnace at this level for about one hour.

Fig. 13: Picture of the thermostat at peak temperature, they maintained the furnace at this level for about one hour.

Short video showing the sound of the furnace shortly before reaching peak temperature.

The aftermath

On April 13 at 9:00 am the test had concluded, the furnace was practically at ambient temperature. The first 3 pictures were taken by Juan when they first opened the furnace, he sent those pics to me. I got really anxious because you can barely see any marks on the plates so for a moment I thought they were completely done. I arrived at 11:30 am to the factory only to be surprised by the results.

Fig. 14: Both plates right after opening the furnace.

Fig. 14: Both plates right after opening the furnace.

Fig. 15: Close up view of the burned Plate S, you can see a small layer of the steel peeled off in tiny flakes.

Fig. 15: Close up view of the burned Plate S, you can see a small layer of the steel peeled off in tiny flakes.

Fig. 16: Close up view of the Board S.

Fig. 16: Close up view of the Board S.

Fig. 17: Close up view of the Plate S' flakes. Unsure at to what exactly these are.

Fig. 17: Close up view of the Plate S' flakes. Unsure at to what exactly these are.

Fig. 18: Close up view of the Board S' flakes.

Fig. 18: Close up view of the Board S' flakes.

Steel backup 1 (Plate S): Heat damage in high detail.

Fig. 19: Burned Plate S, front and back. You can still see all the numbers. The laser engraving is barely visible.

Fig. 19: Burned Plate S, front and back. You can still see all the numbers. The laser engraving is barely visible.

Fig. 20: Burned Plate S, close up view.

Fig. 20: Burned Plate S, close up view.

Fig. 21: Burned Plate S, macro shot. (This image has increased contrast)

Fig. 21: Burned Plate S, macro shot. (This image has increased contrast)

Steel backup 2 (Board S): Heat damage in high detail.

Fig. 22: Burned Board S, front and back. The holes are difficult to see but they are still visible. The laser engraving is completely gone.

Fig. 22: Burned Board S, front and back. The holes are difficult to see but they are still visible. The laser engraving is completely gone.

Fig. 23: Burned Board S, close up view. You can better see the holes.

Fig. 23: Burned Board S, close up view. You can better see the holes.

Fig. 24: Burned Board S, macro shot. (This image has increased contrast)

Fig. 24: Burned Board S, macro shot. (This image has increased contrast)

Fig. 25: Burned Board S with a recovery acetate of the Phrase S, illustrating how to recover the backup.

Fig. 25: Burned Board S with a recovery acetate of the Phrase S, illustrating how to recover the backup.

Fig. 26: Macro shot decoding the Board S with a recovery acetate. Although difficult to see, all holes are still visible.

Fig. 26: Macro shot decoding the Board S with a recovery acetate. Although difficult to see, all holes are still visible.

Results

Disclaimer: The ratings in the scale of 10 are based on my opinion.

Plate S → (Buy Now)

-

Backup data: FULL RECOVERY ✅

-

Ease of recovery: 10/10

-

Steel integrity: 7/10

Board S → (Buy Now)

-

Backup data: FULL RECOVERY ✅

-

Ease of recovery: 6/10

-

Steel integrity: 8/10

Conclusions

After carefully reviewing both burned plates and the nature of this benchmark, I came to the conclusion that this test was a total success. I like that this ended up being an extreme endurance test that really shows the strength of the steel.

There's no secret, if the furnace would have reached a temperature of 1450 °C (2642 °F) both plates would have melted and redeemed irrecoverable. But realistically speaking, in what scenario would these crazy temperatures be reached? The average house fire temperature oscillates between 600 °C and 800 °C (1100 °F - 1500 °F). Source 1 Source 2

I do not claim to be an expert in house fires but I firmly believe that 12 hours of high temperature is a long amount of time and proves that this grade of steel is suitable for this kind of application.

Another important thing to note is that discreetness comes at a cost, as you may have seen in the pictures. The process of recovering the data from the Board S is a bit tedious because all the laser guides from the plate disappeared in the heat, so you would need an acetate with the proper layout to decode the backup. Comparing that with the Plate S, the numbers are directly imprinted into the steel so there is no uncertainty as to what is the correct order or orientation to decode the backup.

I sincerely hope that this high temperature test inspires more confidence to our brand. If you purchase one of our steel backups, you can rest assured that it will keep your key alive even in extreme cases.

***

If you have any other ideas for potential testing on the steel, feel free to leave a comment or contact us via email!

cool!